- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Description:

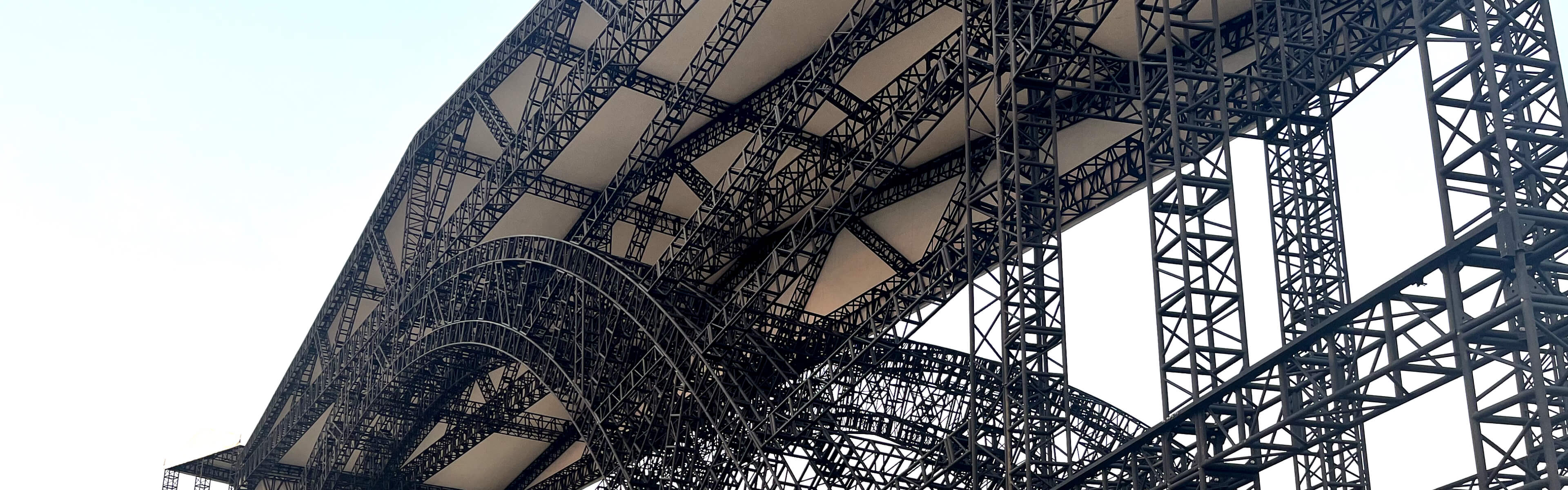

Specialist truss refers to a type of truss system that is designed for specific or specialized applications, such as those required in the aerospace, marine, or industrial sectors. These trusses are typically custom-designed to meet the specific structural and performance requirements of the project, and they may feature unique shapes, materials, or connection systems. Specialist trusses can be made from a variety of materials, including aluminum, steel, carbon fiber, or composite materials, depending on the design specifications and performance requirements of the application.

We can provide you with a general overview of the typical components and structure of such trusses:

Main Chords: The main chords are the horizontal beams that run along the length of the truss. These beams provide the primary structural support for the truss. In a rectangular truss, there are typically four main chords that form the outer perimeter of the rectangle.

Diagonal Bracing: Diagonal bracing elements connect the main chords at an angle to provide additional stability and load-bearing capacity. These braces create triangles within the truss structure, which are known for their strength.

Nodes: Nodes are the junction points where the main chords and diagonal bracing intersect.

These points are crucial for distributing forces and maintaining the stability of the truss.

Spigots and Bolts: Spigots are connectors that allow truss sections to be connected securely at the nodes. Bolts or pins are used to lock the spigots in place, ensuring that the truss sections remain stable during use.

Cross Bracing: In some designs, additional cross bracing might be used to reinforce the truss structure. These braces can be placed diagonally across the rectangular opening or between the main chords.

End Plates: End plates are flat metal plates attached to the ends of the main chords. They provide a surface for connecting the truss to other elements, such as lighting fixtures, signage, or other truss sections.

Lighting Mounts: Many aluminum outdoor rectangular trusses are designed to support lighting fixtures, audio equipment, banners, and other accessories. These trusses often have mounting points or slots where these items can be attached.

Weather Resistance: Outdoor trusses are usually made from aluminum, which is lightweight, corrosion-resistant, and suitable for outdoor use. They may also have protective coatings or finishes to enhance their durability in different weather conditions.

Modularity: Outdoor rectangular trusses are often modular, meaning they can be disassembled and reconfigured as needed. This modularity allows for versatility in setting up different event layouts.

It's important to note that truss designs can vary significantly based on factors such as load requirements, span lengths, intended use, and local safety regulations. When using outdoor rectangular trusses, it's essential to follow manufacturer guidelines, safety standards, and best practices for assembly and installation to ensure the safety of both workers and event attendees.

Description:

Specialist truss refers to a type of truss system that is designed for specific or specialized applications, such as those required in the aerospace, marine, or industrial sectors. These trusses are typically custom-designed to meet the specific structural and performance requirements of the project, and they may feature unique shapes, materials, or connection systems. Specialist trusses can be made from a variety of materials, including aluminum, steel, carbon fiber, or composite materials, depending on the design specifications and performance requirements of the application.

We can provide you with a general overview of the typical components and structure of such trusses:

Main Chords: The main chords are the horizontal beams that run along the length of the truss. These beams provide the primary structural support for the truss. In a rectangular truss, there are typically four main chords that form the outer perimeter of the rectangle.

Diagonal Bracing: Diagonal bracing elements connect the main chords at an angle to provide additional stability and load-bearing capacity. These braces create triangles within the truss structure, which are known for their strength.

Nodes: Nodes are the junction points where the main chords and diagonal bracing intersect.

These points are crucial for distributing forces and maintaining the stability of the truss.

Spigots and Bolts: Spigots are connectors that allow truss sections to be connected securely at the nodes. Bolts or pins are used to lock the spigots in place, ensuring that the truss sections remain stable during use.

Cross Bracing: In some designs, additional cross bracing might be used to reinforce the truss structure. These braces can be placed diagonally across the rectangular opening or between the main chords.

End Plates: End plates are flat metal plates attached to the ends of the main chords. They provide a surface for connecting the truss to other elements, such as lighting fixtures, signage, or other truss sections.

Lighting Mounts: Many aluminum outdoor rectangular trusses are designed to support lighting fixtures, audio equipment, banners, and other accessories. These trusses often have mounting points or slots where these items can be attached.

Weather Resistance: Outdoor trusses are usually made from aluminum, which is lightweight, corrosion-resistant, and suitable for outdoor use. They may also have protective coatings or finishes to enhance their durability in different weather conditions.

Modularity: Outdoor rectangular trusses are often modular, meaning they can be disassembled and reconfigured as needed. This modularity allows for versatility in setting up different event layouts.

It's important to note that truss designs can vary significantly based on factors such as load requirements, span lengths, intended use, and local safety regulations. When using outdoor rectangular trusses, it's essential to follow manufacturer guidelines, safety standards, and best practices for assembly and installation to ensure the safety of both workers and event attendees.