CASES & NEWS

Related News

Related Products

The Backbone of Every Performance: The Hidden Engineering of Stage Safety

Views:

Author: Shinestage

Publish Time: 2025-11-06

Origin:

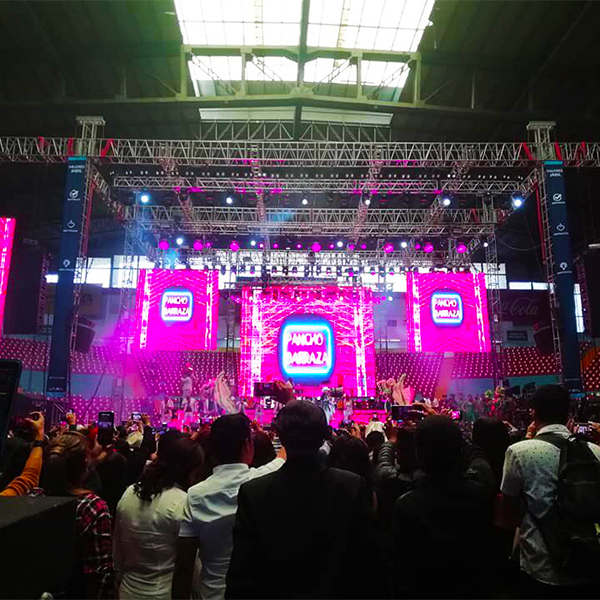

A stage is often remembered for its light, sound, and spectacle—but rarely for the silent precision that keeps it standing. The true beauty of every event lies not only in its design but in the invisible engineering beneath it. The safety of a stage is the backbone of performance itself, the unseen framework that transforms risk into reliability, and imagination into reality.

When thousands of people gather in front of a performance space, they trust that every joint, every truss, and every beam will hold. That trust is not abstract—it’s the direct result of precise calculations, tested materials, and disciplined craftsmanship. Stage safety begins long before the first performer steps onto the platform. It starts in design, in the blueprint where every load point, span, and connection is defined with mathematical accuracy.

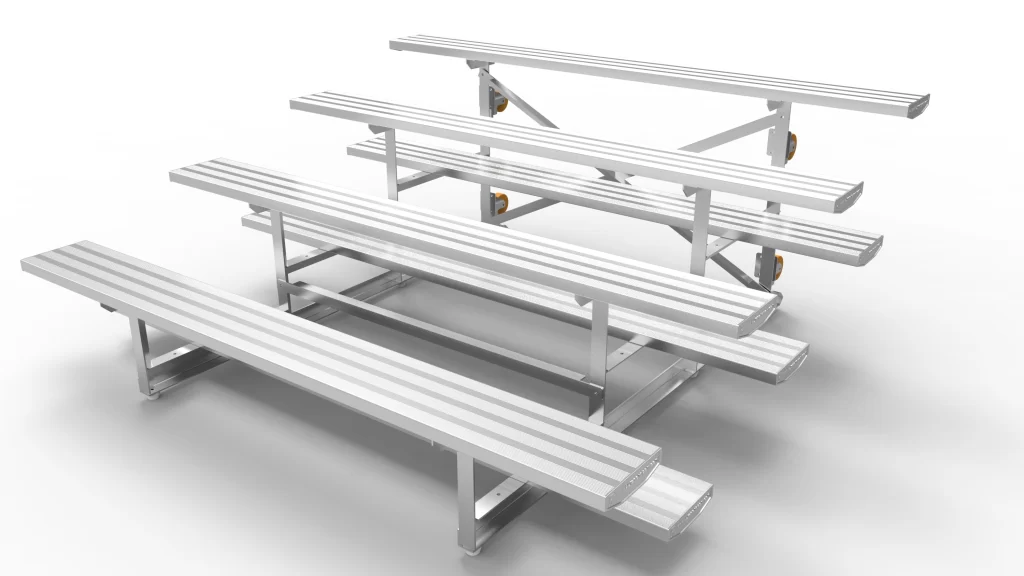

Modern stage systems, especially those built from high-grade aluminum, represent decades of refinement in both material science and mechanical design. Aluminum’s combination of strength and lightness allows structures to support massive loads without sacrificing portability—a critical balance in today’s touring and rental industries. The reliability of these systems is not accidental; it’s the product of thousands of test cycles, fatigue analysis, and international safety certifications that ensure performance consistency.

But safety is not only about material—it’s about structure.

Every truss system is a study in geometry and balance. The triangulated framework distributes weight efficiently, allowing large spans without excessive mass. When properly assembled, a truss behaves like a single solid beam, capable of supporting dynamic loads from lighting, audio equipment, and scenic elements. Engineers must account for not only static weight but also vibration, wind load, and the kinetic energy of movement.

Each stage setup is a complex system of interdependent parts: decks, clamps, connectors, and supports. When one element is compromised, the entire system can lose stability. That’s why professional stage construction relies heavily on standardized components and verified connection methods. Consistency is the key to predictability, and predictability is the essence of safety.

On large outdoor stages, the engineering challenge increases dramatically. Wind pressure, uneven ground, and temperature changes all test the limits of structure and material. The most experienced engineers plan for these variables by designing stages that not only carry weight but also “breathe” with the environment—structures that can flex slightly without losing integrity. This controlled flexibility prevents stress fractures and enhances long-term durability, especially in touring setups that are assembled and dismantled repeatedly.

Testing and certification have become integral parts of stage manufacturing. Every reliable supplier subjects its products to static load tests, torsion evaluations, and simulated assembly cycles. Many work with third-party institutions like TUV or SGS to verify that every component meets international standards. These certificates are not merely documents; they are trust symbols recognized across the global event industry.

The assembly process itself is another dimension of safety engineering.

A well-designed modular system allows crews to assemble quickly and correctly without tools, minimizing the chance of installation error. Clearly marked locking mechanisms, visible height scales, and secure foot pads reduce human error on-site. The best designs make safety intuitive, not complicated—because when the lights are about to go up, simplicity saves time and prevents mistakes.

For stage manufacturers, every design decision must balance efficiency, economy, and endurance. Using thicker welds or reinforced corner blocks may add cost, but they can prevent failure in extreme conditions. Similarly, adopting standardized tube diameters and compatible clamps ensures cross-system stability and simplifies replacement. The more predictable the components, the safer the outcome.

Yet safety extends beyond structure—it also defines reputation.

In the professional staging world, a company’s credibility grows from its record of safe installations. Every successful event builds confidence; every flawless teardown confirms integrity. Stage safety is a language of trust between manufacturer, client, and performer. It ensures that creativity can unfold without fear.

For the end users—production teams, event managers, and touring companies—training is just as important as hardware. Proper load distribution, balanced rigging, and disciplined inspection routines are essential. Even the strongest truss will fail if overloaded or assembled carelessly. True safety culture begins with awareness: understanding that every bolt, pin, and brace has a role, and that every person on-site shares responsibility for stability.

As the scale of live events grows larger and more complex, the industry’s focus on structural safety continues to deepen. Regulations evolve, materials improve, and testing becomes more precise. But at its core, stage safety remains a craft built on experience, respect, and discipline. It is not the most visible part of the show—but it is the one that holds everything together.

When the lights dim and the crowd roars, few will think about the beams under their feet or the welds above their heads. Yet it is those unseen details that make the moment possible. The next time a performer steps confidently onto the stage, that confidence will rest upon thousands of calculations, certifications, and silent guarantees.

Safety is not decoration—it is the quiet soul of performance.

It is the architecture of trust, the geometry of reliability, and the foundation upon which every great moment stands.